All our fabrics are produced in the Prato textile district, within 8 kilometers from our headquarters, through historical partnerships with experienced craftsmen and highly qualified manufacturers.

Our team of designers, thanks to the know-how gained over the years, creates new proposals for each collection and studies customized solutions following client’s requests.

Given the continuous research and strong innovative aspect of our fabrics, in recent years, we have patented some of our most iconic products and registered numerous designs.

Why a proximity production? To follow closely, step by step, each step of our production, to touch and know how one of our fabrics is made and the impact of our work on the environment.This is also fundamental in the design phase to enhance the value of raw materials taking into account possibilities and limits, in order to reduce waste.

All our fabrics are produced in the Prato textile district, within 8 kilometers from our headquarters, through historical partnerships with experienced craftsmen and highly qualified manufacturers.

Our team of designers, thanks to the know-how gained over the years, creates new proposals for each collection and studies customized solutions following client’s requests.

Given the continuous research and strong innovative aspect of our fabrics, in recent years, we have patented some of our most iconic products and registered numerous designs.

Why a proximity production? To follow closely, step by step, each step of our production, to touch and know how one of our fabrics is made and the impact of our work on the environment.This is also fundamental in the design phase to enhance the value of raw materials taking into account possibilities and limits, in order to reduce waste.

Stock service

Milior almost always produces on demand, but sometimes various quantities of fabrics can go unsold. Instead of selling them in stock to to third parties, we keep them in the company to make available to small brands that are launching their first capsule collections. What is left over, we recycle.

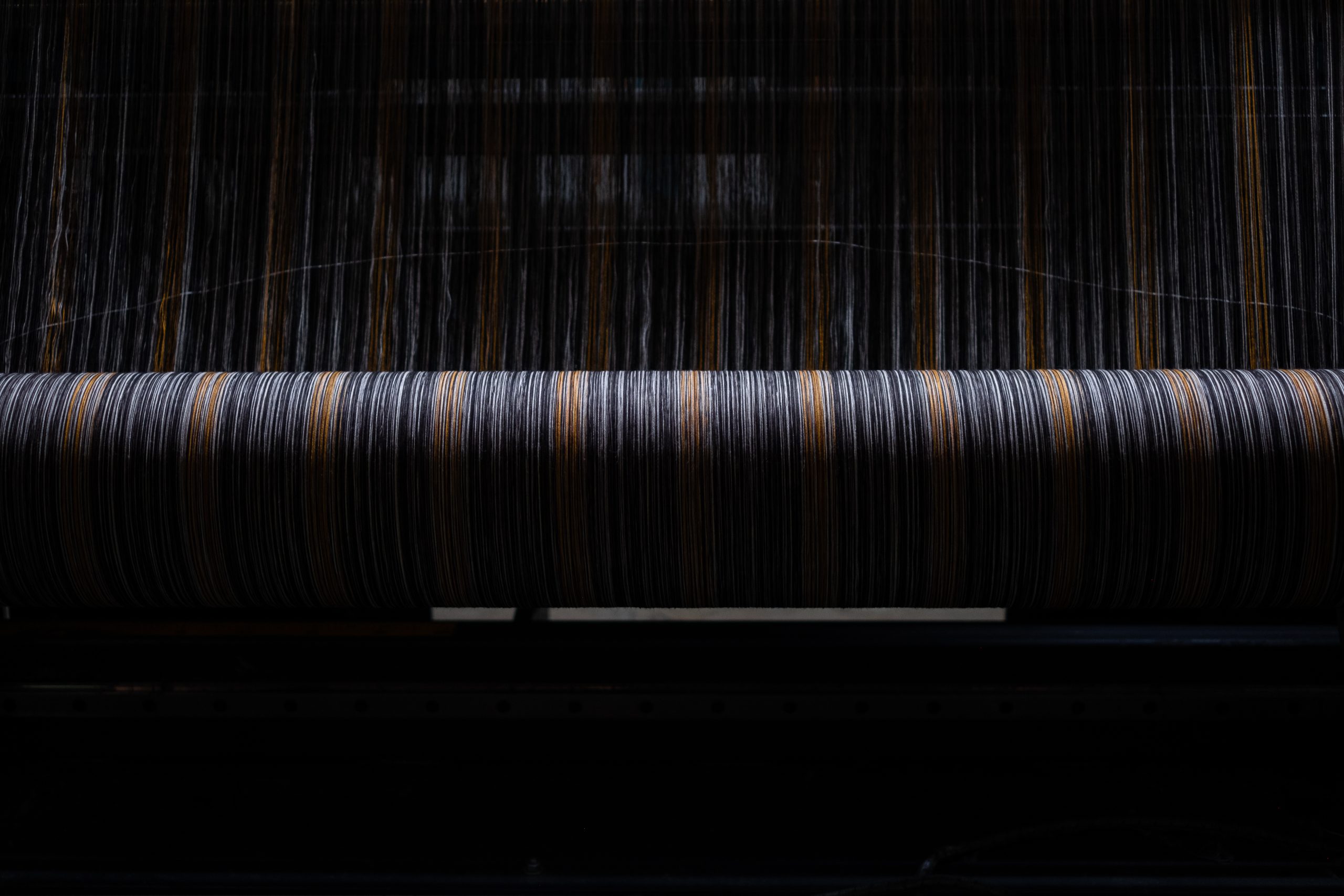

Warping

The internal warping process is carried out on computerised warping machines, guaranteeing excellent quality, thanks also to highly qualified personnel.

We use state-of-the-art machinery suitable for carrying out multiple processes on various types of yarn and, above all, specialised personnel with twenty years’ experience in the sector; thanks to these characteristics we are able to guarantee a high standard of quality, ensuring maximum competence and precision on the part of our personnel, who are always able to carry out impeccable and satisfactory work.

Warping

The internal warping process is carried out on computerised warping machines, guaranteeing excellent quality, thanks also to highly qualified personnel.

We use state-of-the-art machinery suitable for carrying out multiple processes on various types of yarn and, above all, specialised personnel with twenty years’ experience in the sector; thanks to these characteristics we are able to guarantee a high standard of quality, ensuring maximum competence and precision on the part of our personnel, who are always able to carry out impeccable and satisfactory work.

Dye testing

A fully computerised machine, capable of handling the weighing of dye powders, the preparation of the solution and the dyeing of a sample of various fabric sizes. The machine works 24 hours a day in fully automatic mode.

Weaving

To ensure that the fabrics are made exactly as ordered, we have an in-house quality control team. Every piece is checked and any defects are carefully noted. Milior’s customer service is based on efficient timing and minimising complaints.

Weaving

To ensure that the fabrics are made exactly as ordered, we have an in-house quality control team. Every piece is checked and any defects are carefully noted. Milior’s customer service is based on efficient timing and minimising complaints.